When a major online retailer took over a ‘mega-shed’ warehouse near Bolton, Holemasters was appointed by main contractor Winvic to undertake diamond floor sawing of sections of the floor to adapt the warehouse to this specification.

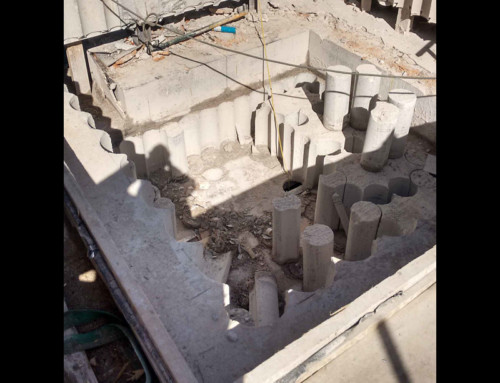

The polished concrete floor covered an area of 400 sqm and contained a high resin content and 15mm rebar reinforcement. A total of 900 holes measuring 3.2 x 3.2 meters square and up to a depth of 200mm had to be precision cut to accommodate 445 stanchions to support their warehouse equipment.

Holemasters carried out all the cutting and drilling work to an extremely tight sectional completion schedule. The work entailed cutting floor slabs into sections to be to be lifted out, as this was quicker than breaking the slabs in situ. Core holes were drilled at each of the corners of the floor openings to prevent overcut.

All these new floor openings required dowel bars to be drilled to maintain the integrity of the slab. Holemasters developed new dowel bar drilling system to achieve a high rate of production and most importantly to eliminate hand to arm vibration syndrome to protect the operatives

The overall project was completed 28.5 days ahead of schedule.